Quickly Get Started Guide

Two Series of Lidding Foils

Tilda provides two typical series of lidding foil solutions, die-cut foil lids and aluminum foil rolls.

Die-Cut Lidding

Our custom die-cut lids are a great way to add style, color, and convenience to your yogurt cups and dairy products. High-quality foil lid seals protect dairy products from air, light and humidity. Our variety of die-cut shapes makes for a perfect fit in almost any container opening. Custom die shapes are available if needed.

Rollstock Lidding Foil

Our rollstock lidding foil is ideal for high-speed packaging operations. This solution seamlessly integrates with automated packaging lines, providing reliable performance without sacrificing quality.

Featured Aluminum Foil Lids for Diverse Markets

We cater to a variety of industries, including food, beverage, nutritional supplements, and consumer goods. Our aluminium foil lids are designed to meet the specific demands of these markets, providing moderate quality at an affordable price.

Let's Talk About Your Foil Needs

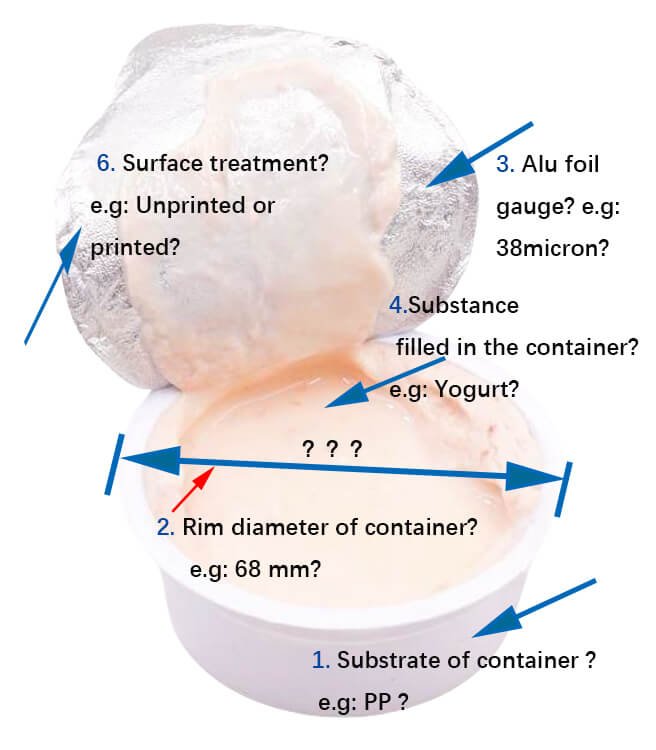

We’re dedicated to understanding your specific requirements. Some key parameters of both cups and lids (e.g: substrate of containers, rim diameters of containers, gauges) shall be requested to help you find the right solution.

Die-Cut Lids

Key information of both containers and aluminium lids for getting backing the quotations and samples

1.Substrate of containers

2.Rim dias of containers

3.Gauge of alu foil

4.Substance filled in containers

5.Filling temperature

6.Surface Treatment

e.g: 30 micron

e.g: Yogurt

e.g: 20~25℃ Cold Filling

e.g: 38 micron

e.g: Water

e.g: 40 micron

e.g: Dips

e.g: 0~8 ℃ Cold Filling

e.g: 50 micron

e.g: Alcoholic beverages

e.g: 6~10℃ Cold Filling

Rollstock Lidding Foil

Essential information of both containers and lidding foil for quotations and samples

1.Substrate of Containers

2.Reel width and roll outer dias

3.Gauge of Alu Foil

4.Core Inner Dias

5.Filling temperature

6.Special Treatment

e.g: 30 micron

e.g: 76 mm

e.g: 20~25℃ Cold Filling

e.g: 38 micron

e.g: 152 mm

e.g: 40 micron

e.g: 76 mm

e.g: 0~8 ℃ Cold Filling

e.g: 50 micron

e.g: 152 mm

e.g: 6~10℃ Cold Filling

Customized

76 / 152 mm

e.g: Hot Filling Cold Filling